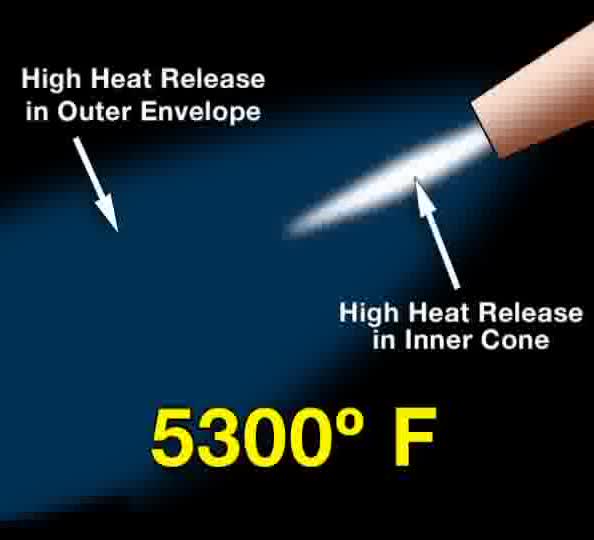

Presents a step-by-step explanation of how to weld, flame cut and braze with the oxyacetylene process.

Pages

- 13. Introduction to oxyacetylene flame cutting

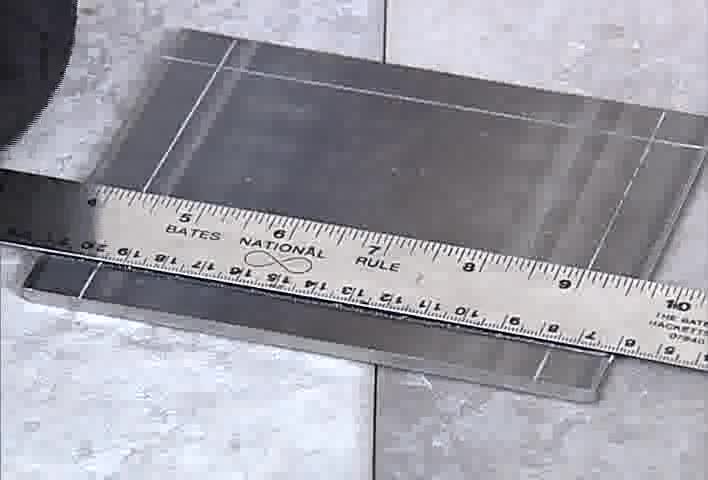

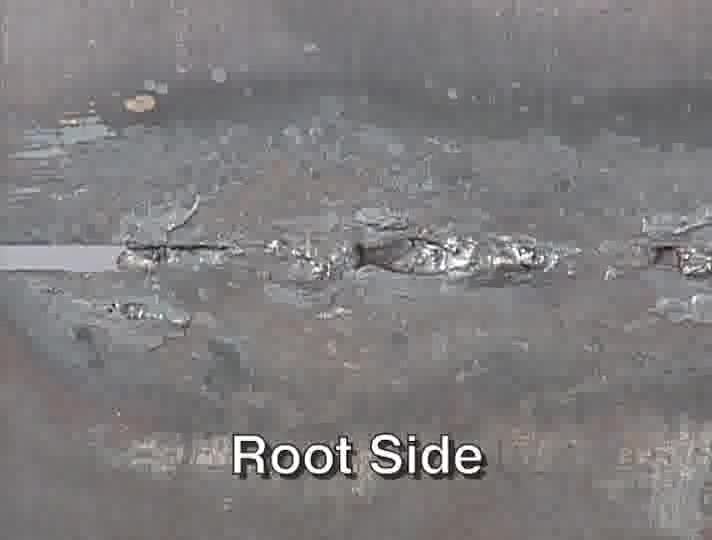

- 14. Standard destructive test, visual inspection and guided bend

- 15. Square groove weld, butt joint, vertical (3G) position

- 16. Square groove weld, butt joint, overhead (4G) position

- 17. Square-groove weld, butt joint, horizontal (2G) position

- 18. Application of fuel gases

- 19. Square groove and bevel hole cuts - manual

- 20. Square groove and bevel hole cuts visual inspection

- 21. Single v-groove weld, butt joint, flat (1G) position

- 22. Single v-groove weld, butt joint, vertical (3G) position

- 23. Single v-groove weld, butt joint, overhead (4G) position

- 24. Single v-groove weld, butt joint, horizontal (2G) position

Pages